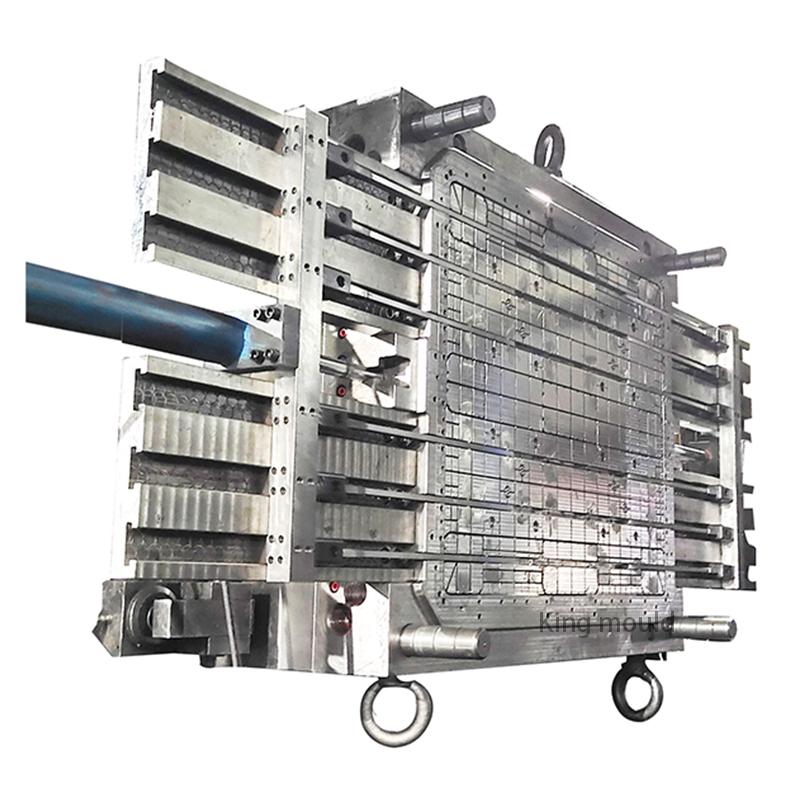

Injection Pallet Moulds are engineered to deliver exceptional performance in the manufacturing of plastic pallets. These moulds are meticulously designed to withstand the high pressures and temperatures inherent in the injection moulding process. The use of premium materials ensures that our moulds maintain their structural integrity over extended periods, even under the most demanding production schedules.

One of the key performance attributes of our Injection Pallet Moulds is their precision. The moulds are crafted to exacting specifications, ensuring that each pallet produced is uniform in size and shape. This precision is critical in maintaining the quality and consistency of the final product, which is essential for industries that rely on pallets for the efficient handling and transportation of goods.

Another performance feature is the moulds' resistance to wear and tear. The use of durable materials and advanced surface treatments extends the life of the moulds, reducing the need for frequent replacements. This not only lowers operational costs but also minimizes production downtime, ensuring a continuous flow of high-quality pallets.

The efficiency of our Injection Pallet Moulds is also noteworthy. They are designed to facilitate quick changeovers and easy maintenance, which helps to optimize production cycles. This efficiency is further enhanced by the moulds' ability to produce pallets with minimal material waste, contributing to a more sustainable and cost-effective manufacturing process.

In summary, our Injection Pallet Moulds offer a combination of precision, durability, and efficiency that is unmatched in the industry. They are the backbone of reliable plastic pallet production, ensuring that manufacturers can meet the demands of their customers with confidence.