Innovation is at the heart of the laser cutting industry, and nowhere is this more evident than in the field of steel pipe cutting. As technology advances, so too does the capability of laser cutting machines to produce more complex and intricate designs with greater precision and speed.

One of the most significant innovations in laser cutting steel pipes is the development of higher power lasers. These advanced lasers can cut through thicker materials and do so more quickly, opening up new possibilities for the design and fabrication of steel pipes. This has led to the creation of pipes with more complex geometries, which can be used in a wider range of applications, from oil and gas pipelines to advanced engineering projects.

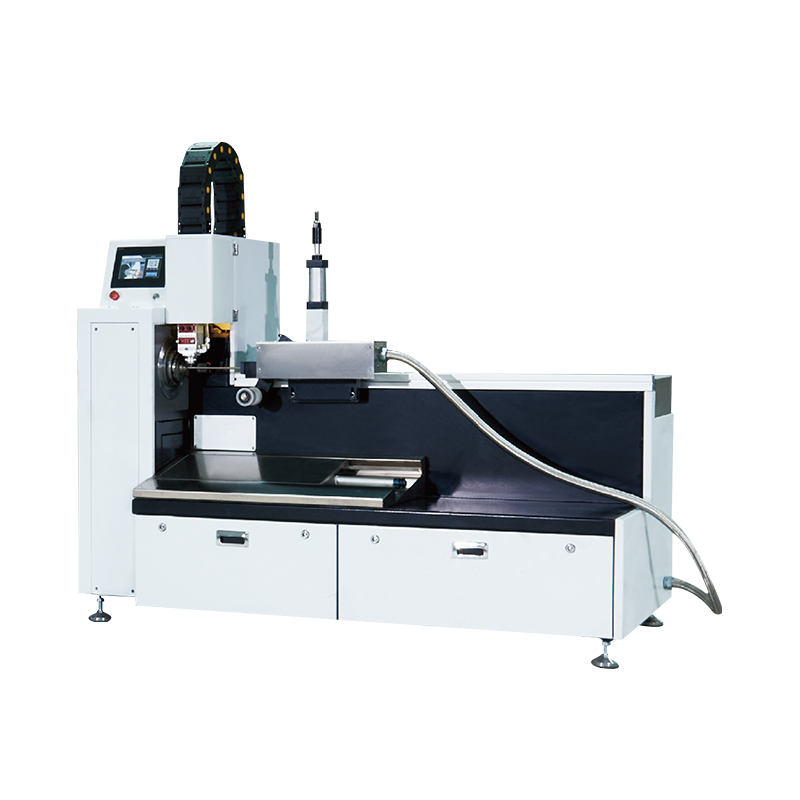

Another innovation is the integration of automation and computer-aided design (CAD) software into the laser cutting process. This allows for the seamless transfer of designs from the computer to the laser cutting machine, reducing the potential for human error and increasing the overall efficiency of the process. Automated systems can also adjust the cutting parameters in real-time to optimize the cutting process, further improving the quality and consistency of the final product.

In addition, the development of fiber lasers has revolutionized the industry. These lasers are more energy-efficient and produce less heat during the cutting process, which reduces the risk of thermal distortion in the steel. This results in cleaner, more precise cuts and a higher quality finished product.

The ongoing research and development in laser technology also promise further innovations in the future. For example, the exploration of ultrafast lasers could lead to even more precise cutting with minimal heat-affected zones, while advancements in laser beam delivery systems could improve the cutting speed and flexibility.

In conclusion, the innovation in laser cutting steel pipes is a testament to the dynamic nature of the industry. As technology continues to evolve, so too will the capabilities of laser cutting, offering new opportunities for the design and fabrication of steel pipes and pushing the boundaries of what is possible in this field.