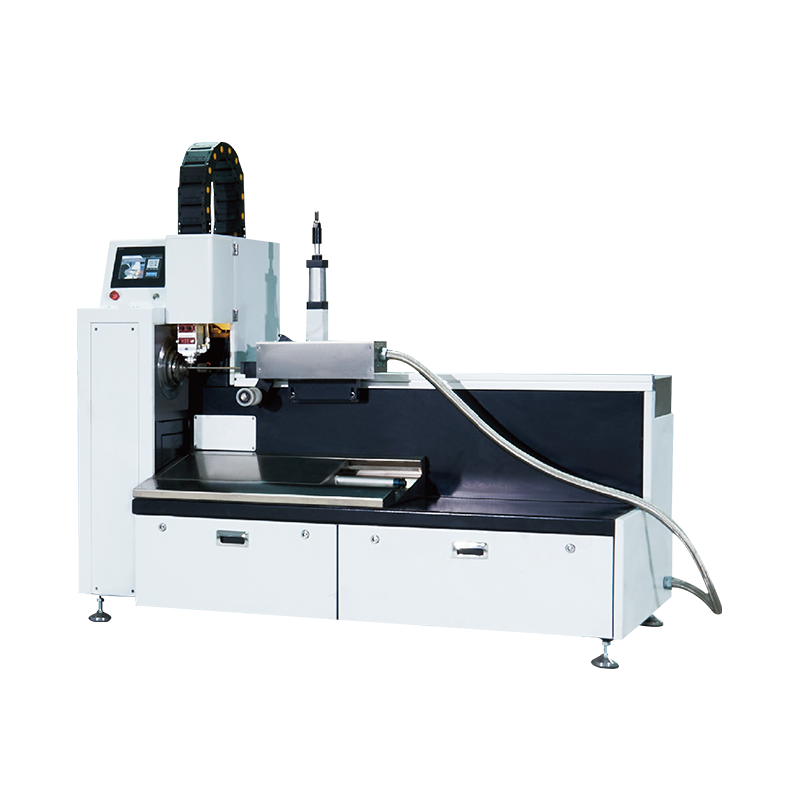

Tube cutting machines are precision engineering marvels designed to meet the demands of industries requiring high-quality, accurate tube cutting. These machines are not just tools; they are integral to the production processes of various sectors, including automotive, aerospace, construction, and furniture manufacturing. The product itself is characterized by several key features that define its utility and efficiency.

Firstly, the cutting accuracy is paramount. Modern tube cutting machines boast advanced cutting technologies that ensure clean, burr-free cuts, which are essential for maintaining the structural integrity of the tubes. Secondly, the machines are designed for versatility, capable of handling a wide range of tube materials, from aluminum to stainless steel, and various diameters and wall thicknesses.

The ease of operation is another critical feature, with user-friendly interfaces and automated processes that reduce the need for skilled labor, thus lowering operational costs. Safety features are also integral, as these machines are equipped with guards and emergency stop mechanisms to protect operators from injury.

Lastly, the durability and reliability of tube cutting machines are non-negotiable. High-quality components and robust construction ensure that these machines can withstand the rigors of continuous operation, reducing downtime and maintenance costs.