In the modern era of industrial production, the Plastic Crate Mould Factory has become a beacon of environmental responsibility, integrating sustainable practices into every facet of its operations. The commitment to environmental protection in a Plastic Crate Mould Factory is not just a regulatory requirement but a fundamental aspect of its corporate ethos. This article delves into the various strategies and initiatives that these factories employ to minimize their environmental footprint and contribute positively to the planet.

The journey towards environmental sustainability in a Plastic Crate Mould Factory begins with the selection of materials. Opting for recycled or bio-based plastics significantly reduces the carbon footprint associated with the production of new plastic materials. Moreover, the use of non-toxic and recyclable materials ensures that the end products are not only safe for use but also easier to dispose of or recycle at the end of their lifecycle.

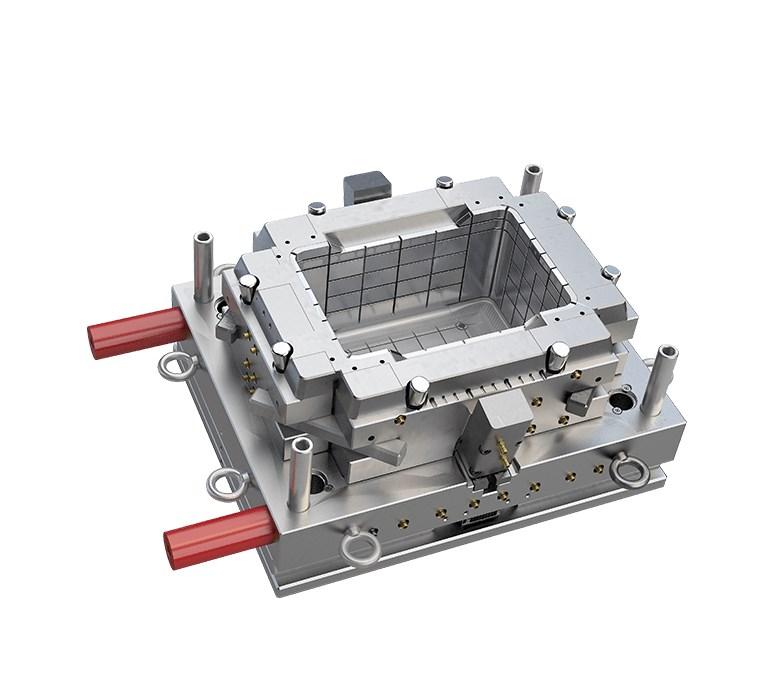

In the design phase, the Plastic Crate Mould Factory focuses on creating molds that are energy-efficient and require less raw material, thereby reducing waste and conserving resources. The use of advanced computer-aided design (CAD) software allows for the optimization of mold shapes and dimensions, ensuring that the crates are lightweight yet robust, minimizing the amount of plastic used in each unit.

The manufacturing process itself is a testament to the Plastic Crate Mould Factory's dedication to environmental protection. Implementing energy-efficient machinery and equipment, such as electric or hydraulic presses, reduces the overall energy consumption of the factory. Additionally, the use of renewable energy sources, such as solar or wind power, further decreases the factory's reliance on fossil fuels.

Waste management is another critical area where the Plastic Crate Mould Factory excels in its environmental efforts. By implementing a comprehensive waste reduction program, factories can minimize the amount of waste generated during the production process. This includes recycling scrap materials, reusing leftover plastic, and ensuring that any waste that is produced is properly disposed of or treated in an environmentally friendly manner.

Water conservation is also a priority for the Plastic Crate Mould Factory. By using water-saving technologies and practices, such as closed-loop cooling systems and rainwater harvesting, these factories can significantly reduce their water consumption. Moreover, any wastewater generated during the production process is treated to remove contaminants before being released back into the environment.

Air quality is another aspect that the Plastic Crate Mould Factory takes seriously. By installing air filtration systems and using low-emission materials and processes, these factories can minimize the release of harmful pollutants into the atmosphere. Regular maintenance and monitoring of air quality within the factory also ensure that workers are not exposed to hazardous levels of pollutants.

Finally, the Plastic Crate Mould Factory's commitment to environmental protection extends beyond its operations. By actively participating in community environmental initiatives, such as tree-planting programs and clean-up drives, these factories demonstrate their dedication to the well-being of the planet and its inhabitants.

In conclusion, the Plastic Crate Mould Factory's approach to environmental protection is a multifaceted one, encompassing every stage of the production process. From the selection of materials to the design, manufacturing, and waste management practices, these factories are leading the way in sustainable manufacturing. By continuously innovating and refining their environmental strategies, the Plastic Crate Mould Factory is not only ensuring the longevity of its operations but also contributing to a healthier, more sustainable future for all.