In the intricate world of electronics, the Board to Board Connector plays a pivotal role in establishing secure and reliable connections between circuit boards. The waterproof performance of these connectors is a critical attribute, especially in applications where devices are exposed to moisture or are used in damp environments. This article delves into the waterproof capabilities of Board to Board Connectors, examining how they are designed to withstand various levels of water exposure and the implications for their use in different settings.

The waterproof performance of Board to Board Connectors is a measure of their ability to prevent the ingress of water, which can lead to short circuits, corrosion, and ultimately, device failure. Manufacturers of these connectors employ a variety of design features and materials to enhance their resistance to water. One common approach is the use of sealant, which is applied around the connector to create a barrier against water penetration. Additionally, the connectors may be designed with a tight fit and robust housing that further shields the internal components from the elements.

The effectiveness of a Board to Board Connector's waterproof performance is often rated according to international standards such as the Ingress Protection (IP) code. This code provides a numerical indication of the level of sealing effectiveness, with higher numbers indicating greater protection. For instance, an IP67 rating means that the connector is dust-tight and can withstand immersion in water up to a certain depth for a specified time. This rating is crucial for applications such as outdoor electronic signage, marine electronics, and industrial equipment that are exposed to the elements.

However, the waterproof performance of Board to Board Connectors is not solely dependent on their design and construction. Proper installation and maintenance are also critical. For example, if a connector is not fully seated or if the sealing mechanism is compromised during installation, water can still infiltrate the connection. Regular inspections and prompt replacement of worn or damaged connectors are essential to maintain the integrity of the waterproof seal.

In high-stakes applications, such as in the automotive industry or aerospace, the waterproof performance of Board to Board Connectors is paramount. These connectors must endure not only water but also other harsh conditions like temperature extremes, vibration, and pressure changes. Specialized materials and treatments, such as gold plating for corrosion resistance and silicone gaskets for enhanced sealing, are often used in these connectors to ensure their reliability in the most demanding environments.

The future of Board to Board Connectors' waterproof performance is promising, with ongoing research and development aimed at improving their resilience to water and other environmental factors. Innovations in nanotechnology, for example, are being explored to create even more effective barriers against water ingress. As technology advances, so too will the capabilities of Board to Board Connectors, ensuring that they remain a reliable choice for connecting circuit boards in even the most challenging conditions.

In conclusion, the waterproof performance of Board to Board Connectors is a multifaceted issue that involves careful design, robust materials, and diligent maintenance. As these connectors continue to evolve, their ability to withstand water and other environmental challenges will be a key factor in their ongoing success and application in a wide range of electronic devices and systems.

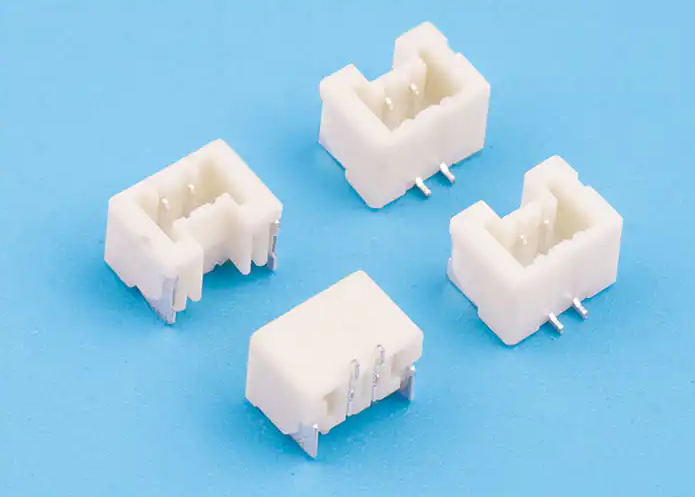

1、CKT: 2Pin

2、Current rating: 1A AC/DC

3、Voltage rating(max): 125V, AC/DC

4、Working Temperature: -25°C~+85°C,

(Including temperature rise in applying electrical current)

5、Contact resistance:value s20mΩ

After environmental testing≤30msΩ

6、Insulation resistance: 2100MΩ

7、Withstand voltage: 500VAC(rms)

8、Applicable PCB board thickness: 1.6mm to 2.0mm