𝐏𝐫𝐞𝐦𝐢𝐮𝐦 𝐇𝐚𝐧𝐝𝐦𝐚𝐝𝐞 𝐑𝐮𝐠𝐬 𝐢𝐧 𝐃𝐞𝐥𝐡𝐢

Delhi has a vibrant market for premium handmade rugs, offering a wide variety of designs and materials. Here are some well-known places and brands where you can find high-quality handmade rugs:

𝐃𝐚𝐬𝐭𝐤𝐚𝐫:This organization supports traditional craftspeople and features a range of handmade rugs and carpets.

𝐊𝐚𝐬𝐡𝐚𝐧 𝐂𝐚𝐫𝐩𝐞𝐭𝐬: Known for their exquisite Persian carpets, Kashan Carpets

offers a selection of high-quality handmade rugs.

𝐑𝐮𝐠𝐬 & 𝐁𝐞𝐲𝐨𝐧𝐝:This store specializes in handmade rugs sourced from artisans across India and offers a variety of styles, including modern and traditional designs.

𝐓𝐡𝐞 𝐑𝐮𝐠 𝐑𝐞𝐩𝐮𝐛𝐥𝐢𝐜: They provide a wide range of handmade rugs that combine traditional craftsmanship with contemporary designs.

𝐉𝐚𝐢𝐩𝐮𝐫 𝐑𝐮𝐠𝐬: Though based in Jaipur, they have a presence in Delhi and offer a range of handmade rugs that emphasize sustainable practices and traditional techniques.

𝐏𝐚𝐧𝐜𝐡𝐚𝐥 𝐑𝐮𝐠𝐬: Known for their exquisite hand-knotted carpets, they offer a variety of designs suitable for different decor styles.

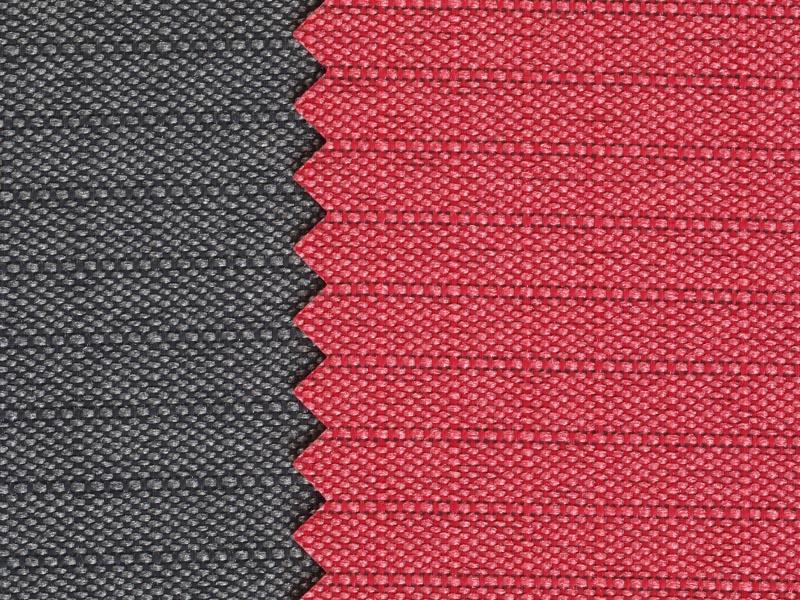

When looking for premium rugs, consider factors like the material (wool, silk, cotton), the weaving technique (hand-knotted, hand-tufted), and the design aesthetics to find the perfect piece for your space.

https://lnkd.in/gUT-wH33𝐏𝐫𝐞𝐦𝐢𝐮𝐦 𝐇𝐚𝐧𝐝𝐦𝐚𝐝𝐞 𝐑𝐮𝐠𝐬 𝐢𝐧 𝐃𝐞𝐥𝐡𝐢

Delhi has a vibrant market for premium handmade rugs, offering a wide variety of designs and materials. Here are some well-known places and brands where you can find high-quality handmade rugs:

𝐃𝐚𝐬𝐭𝐤𝐚𝐫:This organization supports traditional craftspeople and features a range of handmade rugs and carpets.

𝐊𝐚𝐬𝐡𝐚𝐧 𝐂𝐚𝐫𝐩𝐞𝐭𝐬: Known for their exquisite Persian carpets, Kashan Carpets

offers a selection of high-quality handmade rugs.

𝐑𝐮𝐠𝐬 & 𝐁𝐞𝐲𝐨𝐧𝐝:This store specializes in handmade rugs sourced from artisans across India and offers a variety of styles, including modern and traditional designs.

𝐓𝐡𝐞 𝐑𝐮𝐠 𝐑𝐞𝐩𝐮𝐛𝐥𝐢𝐜: They provide a wide range of handmade rugs that combine traditional craftsmanship with contemporary designs.

𝐉𝐚𝐢𝐩𝐮𝐫 𝐑𝐮𝐠𝐬: Though based in Jaipur, they have a presence in Delhi and offer a range of handmade rugs that emphasize sustainable practices and traditional techniques.

𝐏𝐚𝐧𝐜𝐡𝐚𝐥 𝐑𝐮𝐠𝐬: Known for their exquisite hand-knotted carpets, they offer a variety of designs suitable for different decor styles.

When looking for premium rugs, consider factors like the material (wool, silk, cotton), the weaving technique (hand-knotted, hand-tufted), and the design aesthetics to find the perfect piece for your space.

https://lnkd.in/gUT-wH33